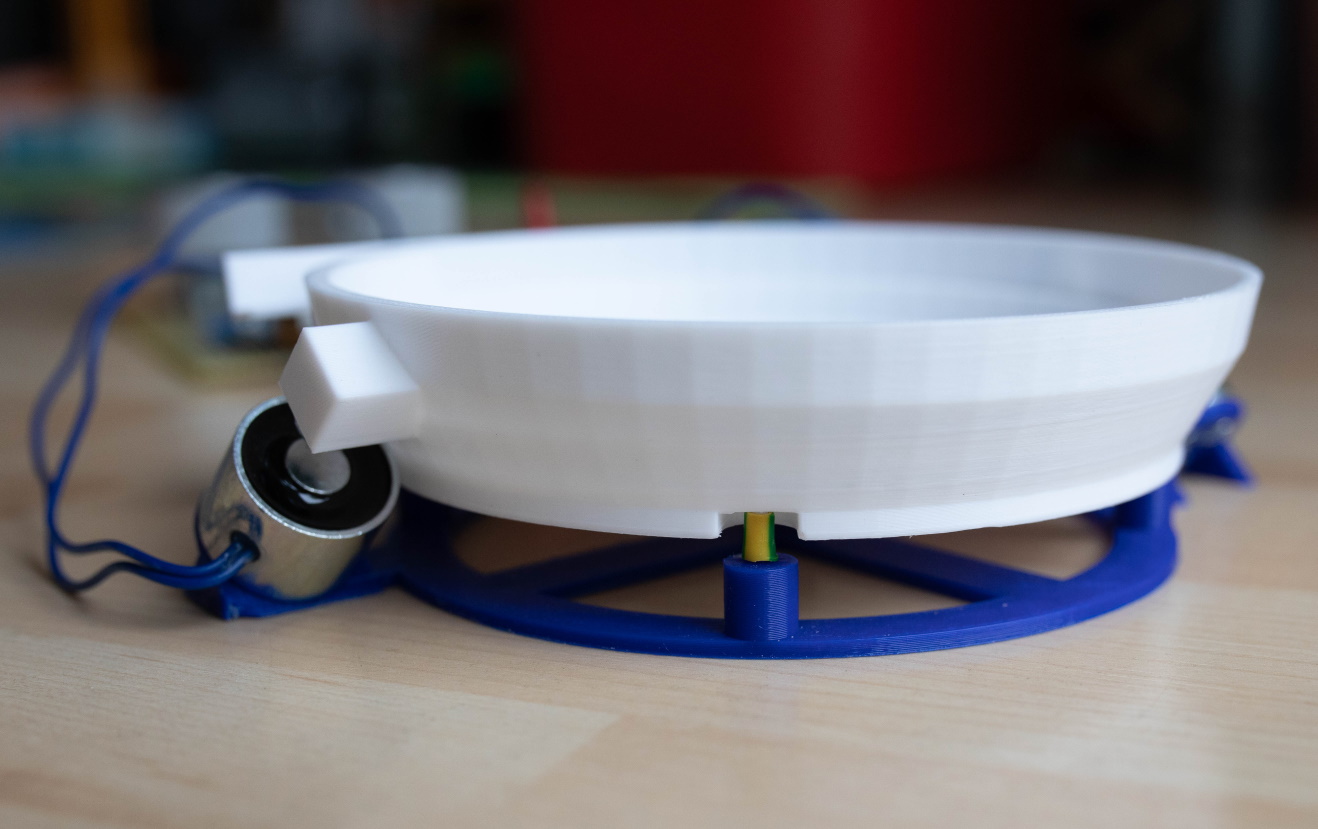

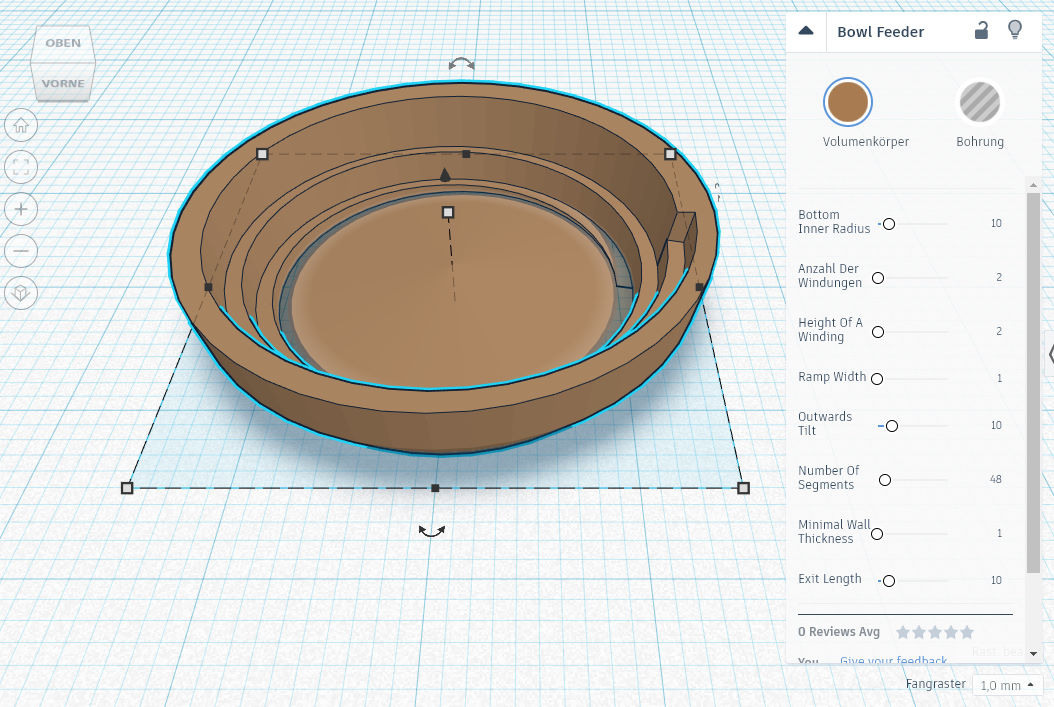

Now that I have finished designing the bowl feeder, it’s the time to get it 3d-printed. I never intended to 3d-print it myself, this would be similar to making printed-circuit boards (PCBs) myself: It would be a huge project of its own and there are companies out there, who offer professional quality at a very good price. But still, one has to understand the challenges of 3d-printing in order to avoid common pitfalls in designing the model.

So I searched the Internet for a suitable printing-service provider. I found https://all3dp.com/, who submit your model to different providers and show you the providers with the best price vs. the shortest delivery time. Both parts, the bowl and the base cost me less than 20€ each incl. shipping and VAT.

Continue reading “3D Printing”